-

Excavator Bucket Bushing

-

Excavator Bucket Pins

-

Excavator Bucket Teeth

-

Used Concrete Pump

-

Used Excavator

-

SANY Excavator Filter

-

SANY Excavator Electric Parts

-

SANY Excavator Hydraulic Parts

-

Excavator Engine Parts

-

Excavator Air Conditioner

-

Excavator Undercarriage Parts

-

Truck Crane Spare Parts

-

Concrete Pump Spare Parts

-

Reach Stacker Spare Parts

-

Motor Grader Spare Parts

-

MichaelVery good buying experience. 100% original, the parts quality is as good as ever.

MichaelVery good buying experience. 100% original, the parts quality is as good as ever. -

KenFast delivery, full range of models, original parts

KenFast delivery, full range of models, original parts

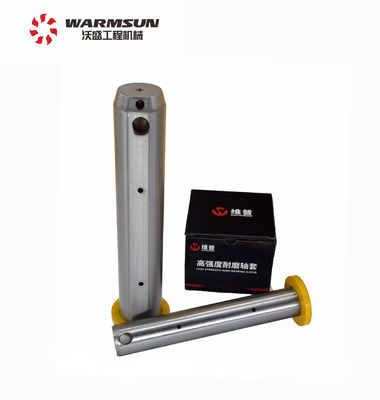

8.100kg A810312110112 90mm Excavator Pins SY130.3.14 For SY135

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | 8.100kg SY130.3.14 Excavator Bucket Pins For Bucket Rod Connection | Model Number | SY130.3.14 |

|---|---|---|---|

| Weight | 8.100kg | Part Number | A810312110112 |

| Measure | 90×90×390mm | Use | Sany SY135 Excavators |

| Highlight | SY130.3.14 Excavator Bucket Pins,A810312110112 90mm excavator pins,90mm excavator pins |

||

8.100kg SY130.3.14 Excavator Bucket Pins

Product Details

We can supply brand new, rebuild and used excavtor spare parts for our customer to choose.

We can supply any product according to your Part Number.

We are the manufacturer with decades of experience in construction machinery industry.

We can ensure the product we provide with most competitive price and high quality.

Every part has its own anti-fake marking, and the company information can be traced by scanning the code of the packing.

The production capacity can meet all kinds of orders from customers.

Pins and bushings can be wholesale, retail and customizable.

Product Parameters

| Headline |

8.100kg SY130.3.14 Excavator Bucket Pins For Bucket Rod Connection |

Brand | Wearproof |

| Part Number | A810312110112 | Model Number | SY130.3.14 |

| MOQ |

1 piece |

Warranty | a full year |

| Part Size |

90×90×390mm |

Use | SY135 Excavators |

| Colour | silver | Origin | China |

|

Inventory |

30000 pcs per season | Port | Shanghai |

| Features | smooth | Sample | yes |

|

Intensity |

10.9 scales |

Weight |

8.100kg |

![]()

Product Processes

There are 7 processes for making a bucket pin

1.cutting ——2.forging ——3.rough machining ——4.quenching and high temperature tempering treatment ——5.finishing ——6.surface hardening, low temperature tempering treatment ——7.grinding

Detailed Procedure

When put steel into the furnace, try to put the round steel of similar thickness into a furnace. The distance between the round steel and the heating resistance wire on both sides is more than 80mm, and the distance between the back end of the round steel and the furnace wall is more than 150mm. If the front end of the round steel is more than 200mm from the furnace door, if the thick and thin round steel is mixed, according to the principle, thin axis will be put on the top and thick axis will be put on the bottom.

When it comes out of the oven, the thin axis comes out first, then the thick axis. Remove the shaft from the oven and soak it vertically in the oil, stirring constantly. When the temperature drops to 150℃ ~ 250℃, remove the shaft from the oil and cool it. The quenched workpiece is reloaded into the furnace, raise the temperature to 620℃ for 2 hours. Finaly, cool the part.

Packing and Shipping

For pins and bushings, a plastic bubble film and a cardboard box are provided to pack goods, which is easy to transport and helps to keep the products intact during transportation.

For leadtime, 10000 pieces are produced per month, which is a large stocks.

For shipping time, every goods will be sent to customers in time. Although shipping time is up to express company, we know an approximate time from different express company, and we will count it into the delivery time. So, our customers could get a precise deadline.

Services

20- year experience in construction machinery industry.

service is attentive.

no customer complaints, no bad comments.

goods can be returned or replaced without any reason within 7 days.

goods can be replaced within 15 days.

warranty is one year.

goods has samples.

FAQ

Q1: Are you trading company or manufacturer?

A: Our management is focused on exporting activities for more than ten years and we have our own bushing factory. Warmsun is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q2: Hong long is your delivery time?

A: It depends on the quantity. For a big order, the time is generally 10-25 days after order. For a small order, customers can get goods at once.

Q3: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed. For some goods that are inconvenient to transport, the express costs will be burdened by the customer

Q4: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.