-

Excavator Bucket Bushing

-

Excavator Bucket Pins

-

Excavator Bucket Teeth

-

Used Concrete Pump

-

Used Excavator

-

SANY Excavator Filter

-

SANY Excavator Electric Parts

-

SANY Excavator Hydraulic Parts

-

Excavator Engine Parts

-

Excavator Air Conditioner

-

Excavator Undercarriage Parts

-

Truck Crane Spare Parts

-

Concrete Pump Spare Parts

-

Reach Stacker Spare Parts

-

Motor Grader Spare Parts

-

MichaelVery good buying experience. 100% original, the parts quality is as good as ever.

MichaelVery good buying experience. 100% original, the parts quality is as good as ever. -

KenFast delivery, full range of models, original parts

KenFast delivery, full range of models, original parts

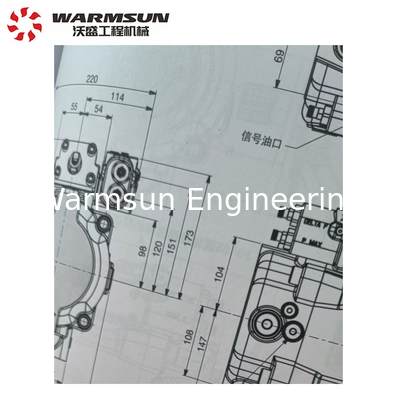

Hydraulic Pump Assembly 60323239 Plunger Pump For SANY Crane P3145L00C1C30TA30V50S1B1E For Parker Pump

| Name | Hydraulic Pump Assembly 60323239 Plunger Pump For SANY Crane P3145L00C1C30TA30V50S1B1E For Parker Pump | Packing Dimension | 470*450*420 Mm |

|---|---|---|---|

| Application | SANY Crane | Model Number | P3145L00C1C30TA30V50S1B1E |

| Part Number | 60323239 | Packing Weight | 86 Kg |

| Highlight | Hydraulic Pump Assembly 60323239,SANY Crane Hydraulic Pump |

||

Hydraulic Pump Assembly 60323239 Plunger Pump For SANY Crane P3145L00C1C30TA30V50S1B1E For Parker Pump

Product Details

1. Pay attention to the cleaning of the hydraulic oil and the cleaning of the iron scraps and iron blocks left by the original pump valve and other accessories in the pipeline.

2. Recommended installation and operation and installation procedures

Maximum speed: 2500RPM

Maximum pressure: 300bar

Flow: 362.51/min (958GPM@2500RPM

Oil inlet conditions: use petroleum-based oil at the highest rated speed, not less than 0.88bar (5.8In-Hg) (vacuum degree). Enter

Oil pressure does not exceed 15bar (217PSI)

Filtration: oil pollution is limited to ISO4406 code 20/18/14

Temperature range: Usually the temperature of the working oil in the tank is 0°C to 70°C (+32 to +158)

The maximum working temperature of casing leakage oil is 90°C (+194)

Cold start temperature -40°C (+40)

Oil: The working viscosity range is between 15-40 field cSt, and the hydraulic oil should have the characteristics of anti-wear, anti-rust and anti-oxidation

Shell leakage: 12L/min (3.2GPM) at 320bar, the maximum back pressure is 1bar (145PSI)

Product Parameters

| Product Name | 60323239 Plunger Pump P3145L00C1C30TA30V50S1B1E For Parker Pump For SANY Crane | Brand Name | Warmsun |

| Part Number | 60323239 | Model Number | P3145L00C1C30TA30V50S1B1E |

| Part Type |

Hydraulic Parts |

Product Material | steel |

| Part Size | 470*450*420 mm | Applicable Industries | Sany crane |

| Product Color | Black | Origin | China |

| Supply Ability | 10000 pieces a month | Port of Dispatch | Guangzhou |

| Part Features | Easy flow adjustment | Samples | yes |

| MOQ | 1 piece |

Weight |

86 kg |

Product Recommend

| 10010680 | flank reinforced board of fixed box |

| 10010686 | bottom board reinforced rib HQC5240JB.20 |

| 10010713 | Front fixed outrigger box body assembly |

| 10010739 | Overwind monitoring component |

| 10010979 | Chassis Harness Assembly |

| 10011017 | Front section of frame |

| 10011671 | Oil suction tube assembly |

| 10011759 | Connecting bushingSYM5242J.17-1 |

| 10011825 | Coupling Sleeve |

| 10012407 | 3-section boom extending rope |

| 10012582 | Hydraulic fluid connection seatQY52.48A- |

| 10013622 | Display control panel |

| 10013678 | Instrument platform componentQY26A.7.2A |

| 10013796 | 25ton chassiscluster assem. |

| 10013822 | Locating shaft QY26A.1.4.1-1 |

| 10014097 | VIce arm electrical diagrams QY26A.10B.3 |

| 10014198 | Control panel drawingQY26A.10B.2.3 |

| 10014340 | Curved plate |

| 10014419 | Amplitude Oil Cylinder |

| 10014475 | Access door |

| 10014476 | Instrument platform component |

| 10014528 | Vertical Outrigger Oil Cylinder |

| 10014620 | Front spring cover boardSYM5242JB.31-3 |

| 10014737 | Transmission shaft base |

| 10014988 | Shaft Sleeve |

| 10015230 | - |

| 10015384 | hoodtail assemblyHQC5420J.8A.1.3 |

| 10015478 | Rear liner plate of hoist box |

| 10015506 | Longitudinal clamping clip |

| 10015507 | Fitting Strip |

| 10015510 | Fitting Strip |

| 10015517 | Engine hood assembly |

| 10015519 | Longitudinal clamping clip |

| 10015618 | Horizontal oil cylinder assembly |

| 10015628 | Hot air and water hose short bracket |

| 10015648 | Water inlet steel tube assembly of engin |

| 10015663 | 4-section boom shrinking rope |

| 10015712 | Air-outlet steel tube support |

| 10015945 | support of outrigger throttle switchSYM5 |

| 10015957 | Oil intake block QY26A.12.4-1 |

| 10016669 | steel tube HQC5420J.41A.2C |

Packing and Shipping

For parts, a plastic bubble film and a cardboard box are provided to pack goods, which is easy to transport and helps to keep the products intact during transportation.

For leadtime, 10000 pieces are produced per month, which is a large stocks.

For shipping time, every goods will be sent to customers in time. Although shipping time is up to express company, we know an approximate time from different express company, and we will count it into the delivery time. So, our customers could get a precise deadline.

FAQ

Q1: Are you trading company or manufacturer?

A: Our management is focused on exporting activities for more than ten years and we have our own bushing factory. Warmsun is always professional and reliable. Our advantages are multiple resource integration, strong quality assurance and excellent service level. We are always responsible for our products.

Q2: Hong long is your delivery time?

A: It depends on the quantity. For a big order, the time is generally 10-25 days after order. For a small order, customers can get goods at once.

Q3: Do you produce samples? Is it free or extra?

A: For standard products, we produce samples free of charge for our customers. And the express costs will be burdened by the customer, but can be returned after the order is placed. For some goods that are inconvenient to transport, the express costs will be burdened by the customer

Q4: How to ensure the quality?

A: We produce as per the confirmed technology or drawings for each order for our customers. And our factory has a strict quality control system. We inspect goods during production according to a certain frequency and we also perform the final inspection before the goods are packed.